- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: shang yu

- Brand Name: QUNSHENG

- Model Number: sbs

SBS Self-adhesive waterproofing materials

Adhesive modified asphalt waterproof coiled material is synthetic rubber modified asphalt and adding suitable amount of active agent, glass fiber mat as matrix (or without) PE film, metal foil as the surface material, or no film (double-sided adhesive), made of silicone oil anti-sticking isolation membrane adhesive modified asphalt waterproofing materials. As self-adhesive coil has certain extensibility, good stability, high strength, corrosion resistance, long service life, etc, applies to ban fire and all kinds of tunnel, the basement, roof, walls and other waterproof engineering. Both during the construction of polymer cement mortar paste directly use shop (wet method), and also can be used according to the traditional construction technology for shop (dry method), meet different requirements of construction projects, construction convenient, fast.

The construction method

1, wet method: clean base, wet concrete, with cement, water cement additives (powder) into slurry, into a mushy. Brush a layer of cement slurry, don't wait for cement dry tore open coil protective film on the shop coil directly, compression good air, on both sides of the coil overflow to some cement slurry is better.

2, dry laid method: clean base, keep dry, use cold bottom oil, on the base thin brush again, and dry. Shop coil when adjusted the position, tore open transparent protective film while rolling coil, coil after the shop to push coil with drum, compression good air. Final inspection again, whether cement.

Product introduction: since the sticky rubber asphalt waterproofing materials based on polymer resin, high quality asphalt as basic material, with polyethylene film, aluminum foil as the surface material, we used from the isolation layer of adhesive waterproof coiled material. Products with a strong bonding performance and self-healing, adapt to the construction of high and low temperature environment. Divided into tire adhesive and no child from two kinds of glue. A tire adhesive upper and lower self-adhesive between subunits, overlying the surface for vinyl film, the surface can be stripped of silicone membrane. No tire adhesive by self-adhesive, on a mix of vinyl film and the silicone oil film.

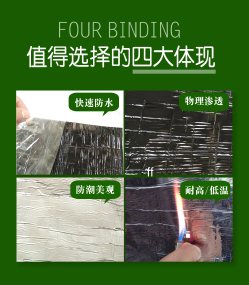

Product features:

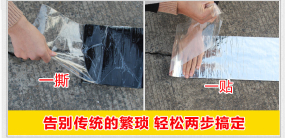

1, no binder, also need not heated baking to melt, just tore to isolation layer, can be bonded firmly at the grassroots level. Construction convenient and extremely fast.

2, with a rubber elasticity, excellent elongation, well adapt to the deformation and cracking at the local level.

3, excellent stick relay at the base, the cohesive force is often greater than the shear force (bonding surface fracture), to ensure reliable lap closely, is perfect.

4, distinctive "self-healing" function, can heal small puncture damage, embedded in a puncture or hard objects, automatically with the object, keep a good waterproof performance.

5, construction safety, polluting the environment, the construction is easy to clean, easy to do the site civilization construction.

6, in addition to the main body material, the surface material of polyethylene film also has excellent waterproof and high intensity (polyethylene polypropylene fiber waterproof membrane is only this), so the waterproof have double insurance.

7, corrosion resistance, the coil has very good acid and alkali resistance, resistance to chemical corrosion, it has excellent resistance to aging performance in various environment.

Product use: apply to industrial and civil building roof, basement,, municipal engineering and reservoir, indoor swimming pool, as well as the subway tunnel waterproof. Also applies to wood and metal structure roofing waterproof project. Especially suitable for the need of cold construction of military facilities and should not use open flame oil base of grain, chemical plants, textile mills, such as waterproof engineering

- Place of Origin: shang yu

- Brand Name: QUNSHENG

- Model Number: sbs

SBS Self-adhesive waterproofing materials

Adhesive modified asphalt waterproof coiled material is synthetic rubber modified asphalt and adding suitable amount of active agent, glass fiber mat as matrix (or without) PE film, metal foil as the surface material, or no film (double-sided adhesive), made of silicone oil anti-sticking isolation membrane adhesive modified asphalt waterproofing materials. As self-adhesive coil has certain extensibility, good stability, high strength, corrosion resistance, long service life, etc, applies to ban fire and all kinds of tunnel, the basement, roof, walls and other waterproof engineering. Both during the construction of polymer cement mortar paste directly use shop (wet method), and also can be used according to the traditional construction technology for shop (dry method), meet different requirements of construction projects, construction convenient, fast.

The construction method

1, wet method: clean base, wet concrete, with cement, water cement additives (powder) into slurry, into a mushy. Brush a layer of cement slurry, don't wait for cement dry tore open coil protective film on the shop coil directly, compression good air, on both sides of the coil overflow to some cement slurry is better.

2, dry laid method: clean base, keep dry, use cold bottom oil, on the base thin brush again, and dry. Shop coil when adjusted the position, tore open transparent protective film while rolling coil, coil after the shop to push coil with drum, compression good air. Final inspection again, whether cement.

Product introduction: since the sticky rubber asphalt waterproofing materials based on polymer resin, high quality asphalt as basic material, with polyethylene film, aluminum foil as the surface material, we used from the isolation layer of adhesive waterproof coiled material. Products with a strong bonding performance and self-healing, adapt to the construction of high and low temperature environment. Divided into tire adhesive and no child from two kinds of glue. A tire adhesive upper and lower self-adhesive between subunits, overlying the surface for vinyl film, the surface can be stripped of silicone membrane. No tire adhesive by self-adhesive, on a mix of vinyl film and the silicone oil film.

Product features:

1, no binder, also need not heated baking to melt, just tore to isolation layer, can be bonded firmly at the grassroots level. Construction convenient and extremely fast.

2, with a rubber elasticity, excellent elongation, well adapt to the deformation and cracking at the local level.

3, excellent stick relay at the base, the cohesive force is often greater than the shear force (bonding surface fracture), to ensure reliable lap closely, is perfect.

4, distinctive "self-healing" function, can heal small puncture damage, embedded in a puncture or hard objects, automatically with the object, keep a good waterproof performance.

5, construction safety, polluting the environment, the construction is easy to clean, easy to do the site civilization construction.

6, in addition to the main body material, the surface material of polyethylene film also has excellent waterproof and high intensity (polyethylene polypropylene fiber waterproof membrane is only this), so the waterproof have double insurance.

7, corrosion resistance, the coil has very good acid and alkali resistance, resistance to chemical corrosion, it has excellent resistance to aging performance in various environment.

Product use: apply to industrial and civil building roof, basement,, municipal engineering and reservoir, indoor swimming pool, as well as the subway tunnel waterproof. Also applies to wood and metal structure roofing waterproof project. Especially suitable for the need of cold construction of military facilities and should not use open flame oil base of grain, chemical plants, textile mills, such as waterproof engineering